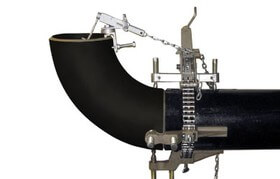

The Double Jackscrew Chain Clamp reforms schedule 40 pipe on either side of the joint to be welded. The jackscrews of the jackbar exert pressure on the high points of both sides of the weld joint to eliminate “Hi-Lo”.

Double Jackscrew Chain Clamp Includes:

- Length of chain required for the pipe range

- Double jackscrew jackbars listed for the pipe range

- Main block

- Fine adjustment

- Level and support device

- Jackscrew wrench

- Storage box

- Parts and operating manual

Optional:

- Carbon or stainless steel Spacing screws

- Add-on Jackbar

NOTE:

- Complete welding of the pipe and fittings can be accomplished without removal of the clamp.

- Add-on jackbar can be added if pressure needs to be applied between the clamp jackbars.

- Jackscrew pads independently pivot to handle uneven surfaces.

- Spacing screws can be added for precise weld gap adjustment.

The Double Jackscrew Chain Clamp reforms Schedule 40 pipe on either side of the joint to be welded. The jackscrews of the jackbar exert pressure on the high points of both sides of the weld joint to eliminate “Hi-Lo”. Pipe wall thickness up to Schedule 80 can be aligned with the clamp.

The level and support device of the chain clamp allows the pipe, elbow, tee, flange and other fittings to be held safely and securely in place during the alignment and welding process.

For stainless steel or specialty alloy applications replace the chain of the standard chain clamp with stainless steel chain.

Available in steel and stainless steel models to fit pipe from 1″ to 54″ (25mm to 1372mm).

FEATURES:

- EXTRA CLEARANCE—Double jackscrew jackbar has extra clearance under the jackbar to better facilitate tig welding torch.

- CRUCIAL ALIGNMENT—The double jackbars, spaced around the outside diameter of the pipe, provide concise alignment and reforming of the internal or external diameters of both pipes within 1/64 of an inch.

- SAFE—Elbows, tees and other fittings can be held safely and securely in place during alignment with the level and support device.

- VERSATILE—The Chain Clamp can be used to support, align, and reform elbow, tees and other fittings that a cage clamp cannot manage. One Chain Clamp covers the range of eight (8) cage clamps.

- READILY REFORMS pipes on both sides of the weld joint to Schedule 40 pipe and aligns Schedule 80 pipes, elbows, tees and other fittings.

Specifications:

| Model | Number of Jackbars | Pipe Size Range | Reforms Pipe to Schedule | Aligns Pipe to Schedule | Est. Ship Wieght |

| D250 | 3 | 1-8 / 25-203 | 40 | 80 | 27 / 12 |

| D250SS | 3 | 1-8 / 25-203 | 40 | 80 | 27 / 12 |

| D249 | 7 | 4-16 / 102-406 | 40 | 80 | 72 / 33 |

| D249SS | 7 | 4-16 / 102-406 | 40 | 80 | 72 / 33 |

| D235 | 8 | 10-36 / 254-914 | 40 | 80 | 144 / 67 |

| D235SS | 8 | 10-36 / 254-914 | 40 | 80 | 144 / 67 |

| D236 | 13 | 10-54 / 254-1372 | 40 | 80 | 180 / 72 |

| D236SS | 13 | 10-54 / 254-1372 | 40 | 80 | 180 / 72 |

SS- Indicates the clamp is Stainless Steel.

Calculations are based on pipe with a yield strength of 45,000 lbs./Sq. in./ 3168kg/sq cm.

DOUBLE JACKSCREW CHAIN CLAMP KIT (Does not include chain)

| Model | Pipe Size Range | Reforms Pipe to Schedule | Aligns Pipe to Schedule | Type of Chain Required | Chain Length Required | Est. Ship Weight |

| D250-KIT1 | 1-8 / 25-203 | 40 | 80 | Note 1 | 3 / 1 | 19 / 19 |

| D249-KIT2 | 4-16 / 25-203 | 40 | 80 | Note 2 | 5 / 1.5 | 59 / 27 |

Does not include tool box.

NOTE: 1. 40-2: riveted nickel plated roller or 40-2: riveted stainless steel roller chain (ANSI#: 40-2R or equal).

NOTE: 2. 60-2: riveted nickel plated roller or 60-2: riveted stainless steel roller chain (ANSI#: 60-2R or equal).

Clamp kit consists of main block, fine adjustment, level and support device, double jackscrew jackbars as required for its range, and operating manual.

| Click here for formulas to calculate chain lengths. |