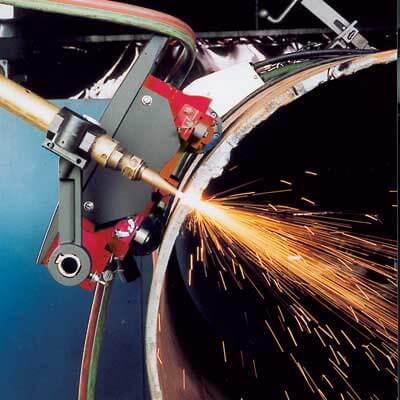

For flame or plasma cutting of any metal pipe

Introducing the world’s most innovative motorised, permanently magnetic pipe and plate cutting machine with a remote-controlled torch arm for pinpoint torch adjustments! Moves around pipe or across plate up to 32″ (813mm) per minute! The MagnaCut II Motor Control Box features a remote-controlled Torch Arm Adjustment, speed and directional control!

Best of all you stay in control of MagnaCut – The magnets never lose their grip under normal conditions. It is recommended to use a safety belt with MagnaCut to avoid possible damage to the machine.

The MagnaCut XM Pipe and Plate Cutting and Beveling Machine will attach to any magnetic receptive surface using powerful permanent magnets located in the wheel assemblies. In the event of a power failure the machine will not lose its grip on the material. The MagnaCut XM has a pipe or tube cutting range of 6 5/8″ (168mm) to unlimited on outer diameter and a 24″ (610mm) inside diameter minimum to unlimited on the inside of the pipe.

- The machine can be mounted at any point on the pipe or plate

- The motorised torch arm provides movement of the torch perpendicular to the line of travel from the MagnaCut

- The motorised torch arm can be used to cut shallow mitres or saddle configurations, when synchronised with the MagnaCut drive motor.

- Motor control available for both 115v and 230v AC.

- Can achieve a maximum cutting speed of 40″ (813mm) per minute and a minimum cutting speed of 2″ (51mm) per minute.

- Guide wheels are provided for cutting large diameter pipes and long length of flat plate.

- Comes with standard storage case.

- A 30mm torch holder is available.

Horizontal or vertical pipe having an outside diameter of 6 5/8″ (168mm) or larger with a wall thickness of 3/8″ (10mm) to 2″ (51mm) can be cut.

Horizontal pipe can be cut internally if it has an inside diameter of 24″ (610mm) or larger with a wall thickness of 3/8″ (10mm) to 2″ (51mm).

It can be used to make longitudinal cuts on a vertical or horizontal ‘I’ beam having a width between the flanges of 20″ (508mm) or larger with a thickness of 3/8″ (10mm) to 2″ (51mm)*

*NB If making vertical cuts on vertical pipe contact Mathey Dearman prior to attempting the application.

Cuts vertical or horizontal plate 12″ (305mm) or larger in width with a thickness of 3/8″ (10mm) to 2″ (51mm)

The MagnaCut will make longitudinal cuts on a vertical or horizontal pipe having a diameter of 16″ (406mm) or larger with a thickness of 3/8″ (10mm) to 2″ (51mm)

Magnacut XM includes:

- Base Machine

- Motor Control Box

- Electric Torch Arm

- Torch Carrier Assembly

- Parts & Operating Manual

- Cutting torch not included

- 74″ long Safety Strap for up to 24″ pipe

- Torch Support

- Hose Support

- 2 Snap hook

- Service Keys

- Storage Box

- Parts and Operating Manual

Options

A 230-115vac Step Down Transformer for 230vac 50/60Hz operation

Available with Torch Holder for 1 3/8” 35mm diameter torch with 24 Pitch or metric torch rack.

Accessories

- 12’/3.7mt Extension Cord for pipe diameters larger than 36”/914mm

- Plasma Torch Adapter for plasma cutting

- Torches and Tips available for all types of cutting gases

- Torch Shut Off Valve to minimize adjustment of cutting torch