Welder working conditions are tough. Its hard to know where you will be working because as probably guessed, pipes don’t move. This means we have to travel to where the pipes are. Whether it’s in Alaskan ice, desert heat or underground, pipes need repairing. Oli and gas companies contact pipeline welders, then they travel to the pipeline. Where ever there are pipelines – oil industry, natural gas, water or sewers – there’s a need for pipeline welding.

Duties

Pipeline welding is the least predictable welding career as most pipeline welders are expected to travel from one site to the next. Travelling is a big past of pipeline welding, meaning the job could be hours away from where you are based. Work hours may run overtime due to this, so if travelling isn’t appealing to you this may not be the best career in welding.

Many of pipeline welding jobs involve studying the pipeline or the specification, and figuring out the dimensions needed for the weld, whilst using the arc welders or other equipment’s to do so.

Working Conditions

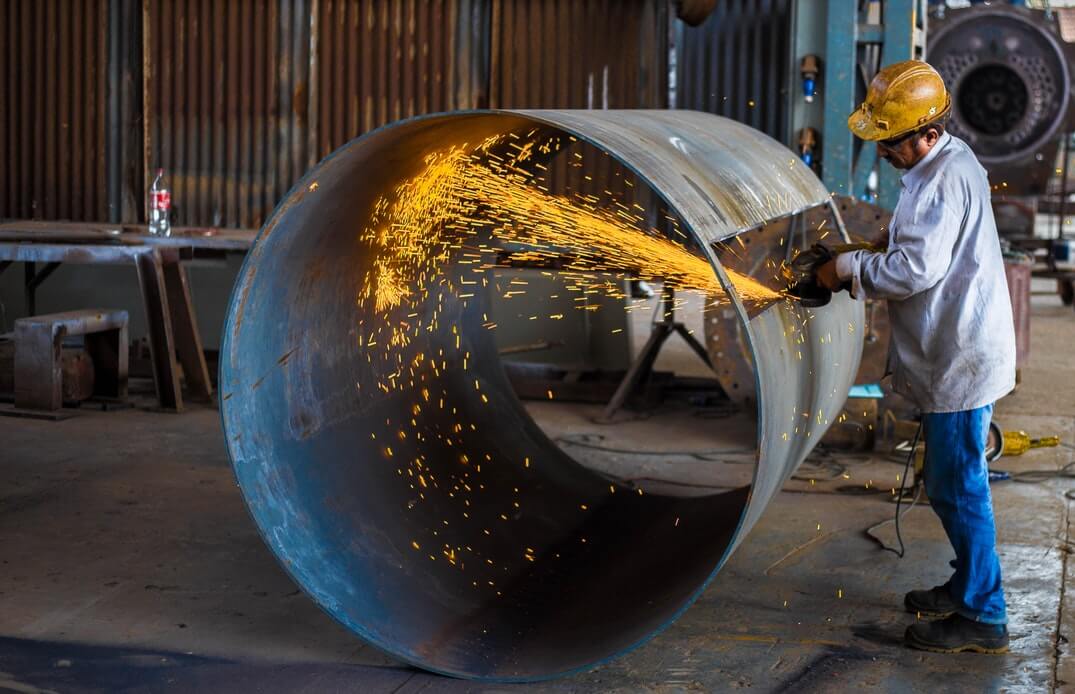

Pipeline welders in any company or branch are at a high risk of injury and illness at all times. For example, the intense light from arc welders and other equipment’s can damage eyesight. Welding tools also generate tremendous amounts of heat, as well as inhaling gases or particles during the welding process. There are many ways which risks can be reduced. Some safety procedures include:

- Wearing equipment such as lenses and heat resistant gloves

- Fire resistant clothing

- Helmets with side shields

- Respirators

Pipeline welding takes working conditions one step further than other welding careers. Some pipeline jobs are at extreme temperatures including deserts. This heat combined with generated heat from a weld can be very challenging. A common site for a pipeline welder is also a sewer. In order to do this job, you must control your gag reflex and avoid contaminating yourself. The most extreme environment is an underwater pipeline. Special equipment means welders can go underwater to do what needs to be done, this is an immense amount of pressure on a welder. Between bubbles and dim light, its difficult to see what you’re doing.

Becoming a Pipeline Welder

Pipeline welding revolves around arc welds, these are extremely difficult and require lots of training. Arc welding is a type of welding process using an electric arc to create heat to melt and join metals. The arc is formed between the actual work and an electrode (stick or wire) that is manually or mechanically guided along the joint. Welders typically start as apprentices or helpers to an established welder who can then teach them the ropes.

Few people are interested in pipeline welding. The requirements are difficult and the conditions are extreme, but the money for this career definitely shows a reflection of the work. If pipeline welding does not interest you further down the line, certifications and skills can transfer to other welding careers, so you aren’t tied down to one job.

What industries can I work in?

While the gas and oil industries do hire a large amount of pipeline welders, those aren’t the only industries you can work in. The pipeline construction industry also deals with a large amount of piping that requires the work of a pipeline welder.

Because so many industries need pipeline welders, it’s possible to find a job where you aren’t expected to travel very often. However, there are jobs for pipeline welders where some travel is required. If you’ve always wanted to see the world, it’s an excellent opportunity.

As mentioned above, not every pipeline welding path follows the same mould. Therefore, it is recommended to make sure you look at the different industries and see which suits you.